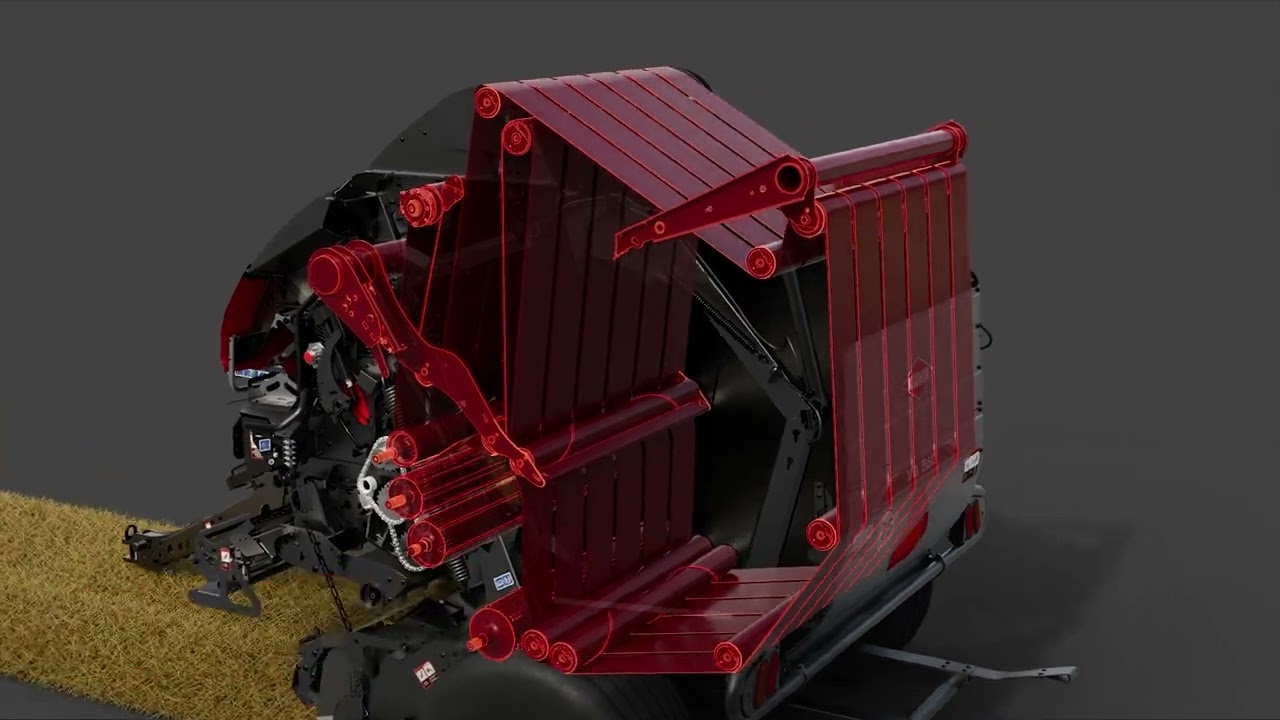

This project marks Kuhn North America’s first fully in-house animation. By transitioning to internal production, we’ve achieved this quality of animation at just 1/6 of our previous costs!

Technically, one of the most challenging aspects was ensuring the baler’s belts remained flexible and properly formed while spinning. Additionally, configuring the particle system to feed into the machine correctly and disappear at the precise moment required meticulous attention.

I particularly enjoyed focusing on the camera work, striving to maintain continuous shots for as long as possible. This project was so enjoyable that I almost applied my face as a material on one of the machine’s cogs.

This project marks Kuhn North America’s first fully in-house animation. By transitioning to internal production, we’ve achieved this quality of animation at just 1/6 of our previous costs!

Technically, one of the most challenging aspects was ensuring the baler’s belts remained flexible and properly formed while spinning. Additionally, configuring the particle system to feed into the machine correctly and disappear at the precise moment required meticulous attention.

I particularly enjoyed focusing on the camera work, striving to maintain continuous shots for as long as possible. This project was so enjoyable that I almost applied my face as a material on one of the machine’s cogs.